Monitoring EMF Radiation from Commercial Microwave Ovens

Commercial microwave ovens play a crucial role in the food service industry, offering rapid and efficient food heating and cooking. However, concerns regarding potential health and safety issues related to electromagnetic field (EMF) radiation from these appliances have emerged.

Like domestic microwave ovens, commercial microwaves rely on a magnetron to generate microwave radiation. The magnetron produces high-frequency electromagnetic waves, typically at 2.4 GHz, which are used for heating food.

Commercial microwave ovens can emit higher levels of EMF radiation compared to residential models due to their increased power and usage. This elevated power allows for faster cooking times but may raise concerns about EMF exposure for kitchen staff who operate these ovens regularly.

Health and Safety Around Microwave Ovens

Prolonged Exposure for Kitchen Staff

Commercial kitchen staff who work near these powerful microwave ovens may experience prolonged exposure to EMF radiation. Prolonged exposure to higher EMF levels could potentially lead to discomfort, heat stress, or other health issues. Adequate ventilation and workspace design can help mitigate these concerns.

Electromagnetic Hypersensitivity (EHS)

Some individuals claim to experience symptoms of electromagnetic hypersensitivity (EHS) when exposed to EMF radiation. These symptoms can include headaches, fatigue, and sleep disturbances. While scientific evidence supporting EHS remains limited, employers should be aware of employee concerns and address them accordingly.

Maintenance and Safety

Regular maintenance and safety checks are essential for commercial microwave ovens. Damaged seals or faulty components can lead to radiation leakage, posing potential health risks for kitchen staff. Employers should establish protocols for maintenance and safety inspections to ensure the ovens are in optimal working condition.

Measuring EMF Radiation from Commerical Microwave Ovens

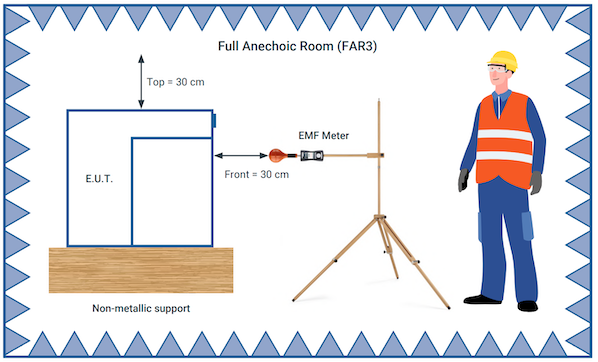

To measure the EMF for this application, we need a Wavecontrol SMP3 EMF meter, a Wavecontrol WPF3 probe, and a wooden tripod.

The SMP3 serves as an instrument designed for the measurement of electromagnetic fields, with its frequency range contingent upon the specific field probe employed. A range of compatible probes is available, from DC (0 Hz) to 60 GHz. SMP3 has been developed to meet the needs for personal safety assessment in connection with exposure to electromagnetic fields.

The SMP3 is available in three fundamental models:

- Broadband: tailored for use with broadband probes.

- Selective: designed for use with selective probes.

- Dual: a versatile model compatible with all probe types, as it combines both features.

The SMP3 is easy to carry and operate. It efficiently records continuous field-level data and stores it automatically at intervals set by the user in its built-in memory, which can accommodate up to 1,000,000 samples.

For subsequent analysis, the data residing in the memory can be effortlessly transferred to a computer via either a USB or fibre optics port. The SMP3 can be equipped with an optional built-in GPS receiver, facilitating automatic geographic location tagging for each measurement.

The purpose of using a wooden tripod in this scenario is to provide a stable and non-conductive platform for positioning the SMP3. Wood is an excellent insulator, which means it does not conduct electricity. Using a wooden tripod reduces the risk of electrical shock or short circuits, as wood is non-conductive and helps maintain a safe working environment for personnel.

Method

Ensure you follow safety precautions when working with microwave ovens, as they emit potentially harmful radiation. Do not tamper with the oven's operation. Ensure you have the appropriate probes or sensors for the microwave frequency (typically 2.45 GHz for household microwave ovens).

Place the SMP3 meter close to the front door of the microwave oven, near the glass window, but outside the oven cavity. Ensure it is stable and does not obstruct the door's sealing. Turn on the microwave oven and set it to run for a brief period, such as 10 seconds, on high power. A short duration is used to minimise exposure to potentially harmful radiation.

To measure both electric (E) we opted for the WPF3 probe, which can accurately assess frequencies ranging from 100 kHz to 3 GHz. Our choice of the WPF3 probe is primarily driven by its dual capability to measure electric field while also staying within the frequency range of interest, up to 2.45 GHz.

- Electric Field Measurement

- Isotropic & True RMS Measurements

- Spectrum Analysis Probe for In-Depth Analysis

- Compliance with International Standards for Accurate Measurements

The measurement should be done by following the steps below.

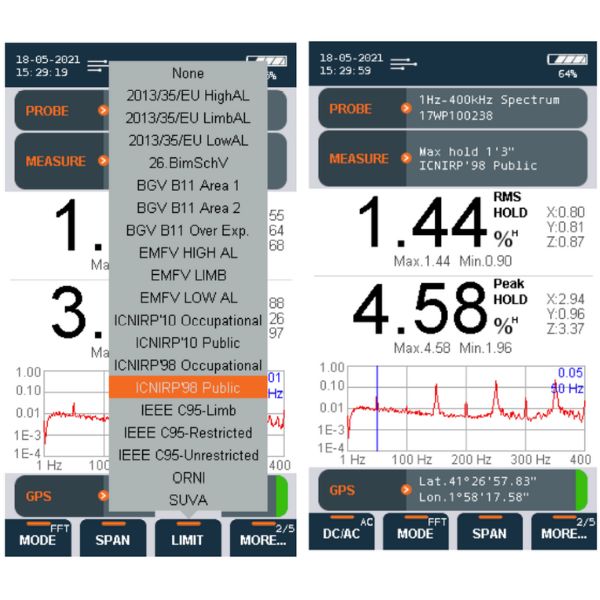

- Choose E field on the SMP3 meter

- The measurement is done according to the Australian standards. These limits are set to ensure the safety of individuals regarding potential health risks associated with EMF exposure.

- Set the measurement mode to 'FFT' (Fast Fourier Transform): FFT is a mathematical technique used to analyse frequency components within a signal.

- Ensure HOLD is set to 'Max' (Maximum): This setting captures and records the maximum H field strength during the measurement.

- The SMP3 should be positioned at approximately 30cm from the electromagnetic field source.

- After setting up the SMP3 and ensuring it's in the correct position, initiate the measurement by pressing the 'LOG' button. The device will record the measurement data.

- It's important to allow enough time after the microwave has stopped to ensure that the measured field strength stabilises and that you've captured the maximum value. This step is crucial to obtain accurate results.

- If the measured Root Mean Square (RMS) value is below 100% of the specified limit, it suggests that the electromagnetic field exposure is within acceptable safety levels. If the measurement exceeds the limit, further actions may be required to mitigate EMF exposure risks or ensure compliance with safety standards.

- While the oven is running, observe and record the EMF measurements displayed on the SMP3 meter. Take readings at various points along the front door, including the window and the seal area.

Remember that measuring EMF in microwave ovens can be potentially hazardous, so exercise caution. If you have concerns about the safety of your microwave oven, consider seeking professional assistance for testing and evaluation.

Like to know more?

Would you like to know more about the SMP3 EMF Meter? Get in touch with the ADM Nuclear Technologies team today!